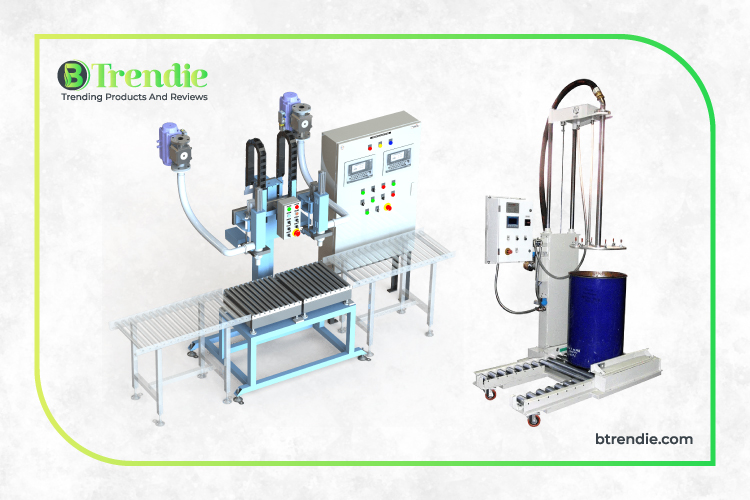

Drum filling machines and systems are essential equipment for companies that deal with liquids, chemicals, and other viscous products. These machines are designed to accurately and efficiently fill drums of various sizes with different types of substances. In this article, we will discuss the importance of drum filling machines and systems, their benefits, and how they can help businesses streamline their operations.

The Importance of Drum Filling Machines and Systems

Drum filling machines and systems are crucial for companies that need to package and transport large volumes of liquid products. These machines ensure that each drum is filled accurately and consistently, eliminating the risk of over or underfilling. They also reduce spillage, waste, and contamination, improving product quality and integrity.

Moreover, drum filling machines and systems are designed to be highly automated, minimizing the need for manual labor and increasing productivity. They can handle a wide range of drums and containers, from small to large, and can fill them at varying rates, depending on the specific requirements.

Benefits of Drum Filling Machines and Systems:

Investing in drum filling machines and systems can yield many benefits for businesses. Here are some of the most significant advantages:

Increased Accuracy: These machines are designed to fill drums accurately and consistently, ensuring that each drum is filled to the exact amount needed.

Reduced Waste and Spillage: By eliminating human error and providing better control over the filling process, drum filling machines and systems reduce waste and spillage, saving businesses money in lost product.

Enhanced Product Quality: These machines minimize the risk of contamination, improving product quality and integrity.

Improved Safety: Drum filling machines and systems are designed with safety features, such as automatic shut-off valves, to prevent accidents and injuries in the workplace.

In addition to the benefits discussed above, drum filling machines and systems are also flexible and customizable. These machines can be designed to fit specific requirements, such as filling drums with different substances, at varying rates, and in various sizes. This flexibility makes them an ideal choice for businesses that need to package and transport different types of liquids and chemicals.

Moreover, drum filling machines and systems can also be integrated with other equipment, such as conveyors, labeling machines, and palletizers, to create a complete packaging line. This integration streamlines the entire process, reducing manual labor, increasing efficiency, and improving overall productivity. By choosing the right combination of equipment, businesses can create a fully automated packaging line that meets their specific needs and requirements.

Improved Efficiency: Drum filling machines and systems automate the filling process, eliminating the need for manual labor and reducing time and costs associated with filling drums.

Drum filling machines and systems are essential equipment for companies that deal with liquid products. They offer significant benefits, including improved efficiency, increased accuracy, reduced waste and spillage, enhanced product quality, and improved safety. Investing in these machines can help businesses streamline their operations, reduce costs, and improve their bottom line. Therefore, it’s crucial for businesses to consider investing in drum filling machines and systems to improve their operations and remain competitive in their industry.

See more about – QWORDLE